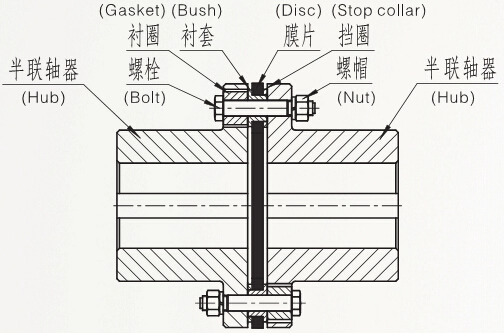

Structure and Application of Disc Couplings

The structure characteristics and application of disc couplings.

A disc coupling connects the drive end and the driven end in order to transmit power and movement by mainly relying on metal elastic disc. It owns many advantages such as vibration attenuation, no noise, no lubrication, etc. The axial, radial and angular deviations are compensated through the deformation of intermediate elastic components.

Disc coupling has the following characteristics:

1) Buffering, vibration attenuation and no noise.

2) No lubrication, no sealing, strong ability to adapt to the environment and safety work under -80℃~+300℃.

3) It can compensate two axes and relatively offset.

4) Simple structure, light weight and convenient usage and maintenance.

5) Easy to balance and suitable for high-speed transmission shafting.

6) No speed discrepancy and suitable for precision transmission.

Disc flexible coupling is widely used in machinery equipments to transfer power such as metallurgy, mining, petroleum, electric power, shipbuilding, lifting machinery, water pumps, paper industry, light industry, printing, chemical engineering and other industries.

Elastic components are the core parts of disc coupling, which determine the good or bad performance of the coupling. The disc of disc coupling produced by our company is conducted the strength design by applying finite element method. Moreover, we optimize the design for the disc’s shape and flexibility by using computer technology. Disc processing is made of high-quality stainless steel spring plate.

Overall coupling has the following advantages:

1) Disc material is 304 stainless steel spring plate, which has high strength, heat resistance and good corrosion resistance performance.

2) The production of disc uses a formation of compound die cold stamping. It has high dimensional accuracy and good consistency.

3) Both ends of the shaft sleeves and the connecting hole of disc coupling adopt CNC machining to ensure interchangeability.

4) The surface-treated and high strength attachment bolts of 12.9 classes ensure its high reliability and anti-corrosive property.

For more information concerning disc couplings, please refer to the following articles:

Structural Types of Disc Couplings

Model Selection of Disc Couplings

Carrying and Storage of Disc Couplings

Installation and Adjustment of Disc Couplings

Usage and Maintenance of Disc Couplings

Basic Info for Model Selection of Disc Couplings

For more information concerning disc couplings, please refer to the following articles:

Structural Types of Disc Couplings

Model Selection of Disc Couplings

Carrying and Storage of Disc Couplings

Installation and Adjustment of Disc Couplings

Usage and Maintenance of Disc Couplings

Basic Info for Model Selection of Disc Couplings