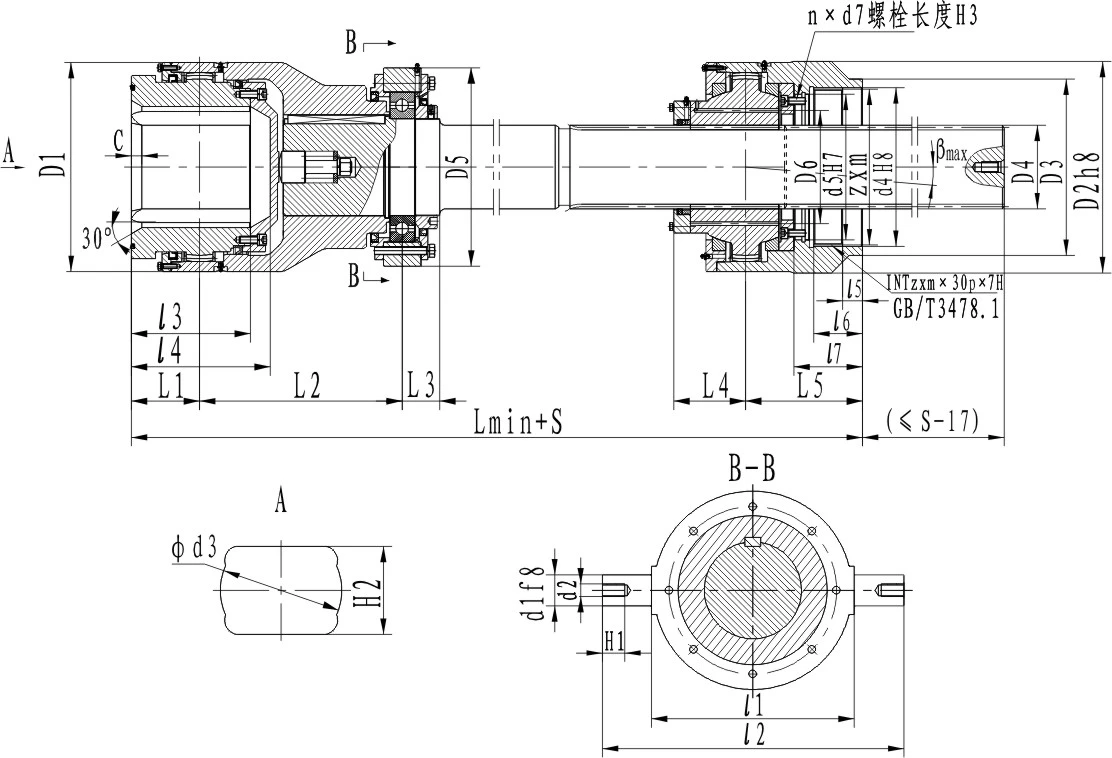

Mill Spindle Gear Coupling - GZZ Type

Key Specifications / Features

Model No.: Suoda 15 GZ 04 Hits: 4319

China Mill Spindle Gear Coupling Manufacturer Suoda Offers Mill Spindle Gear Couplings, GZZ Type Gear Couplings, Heating Treatment, Anti-corrosion.

Request a quote

Share

Tags:

Next: Spindle Coupling - GZC Type

Previous: Rolling Mill Gear Coupling - GZF Type

Detail Infomation

| SIZE |

NOMINAL TORQUE |

WORKING SHAFT |

OVERALL DIMENSION | STROKE | TRUNNION SIZE | |||||||||||||

| Tn | knuckle line | L1 | L2 | L3 | L4 | L5 | Lmin | D1 |

D2 (h8) |

D3 | D4 | D5 | d1 | L1 | L2 | d2×H1 | ||

| kNm | β | (f8) | ||||||||||||||||

| GZZ200 | 31.5 | ≤1.5° | 90 | 250 | 50 | 80 | 190 | 710 | 200 | 200 | 170 | 88 | 200 | 500 | 40 | 200 | 345 | M20×35 |

| GZZ250 | 50 | 105 | 280 | 60 | 90 | 195 | 780 | 250 | 258 | 220 | 105 | 250 | 45 | 270 | 425 | M20×35 | ||

| GZZ285 | 80 | 115 | 315 | 60 | 105 | 205 | 850 | 285 | 270 | 245 | 120 | 270 | 50 | 278 | 442 | M20×40 | ||

| GZZ300 | 100 | 115 | 315 | 62 | 108 | 205 | 855 | 300 | 280 | 250 | 124 | 280 | 600 | 50 | 292 | 487 | M24×45 | |

| GZZ335 | 140 | 130 | 360 | 65 | 135 | 235 | 975 | 335 | 330 | 280 | 150 | 300 | 55 | 293 | 488 | M24×45 | ||

| GZZ355 | 180 | 130 | 360 | 75 | 145 | 245 | 1005 | 355 | 350 | 310 | 174 | 330 | 55 | 312 | 505 | M24×45 | ||

| GZZ390 | 224 | 140 | 390 | 80 | 155 | 255 | 1070 | 390 | 380 | 335 | 180 | 360 | 60 | 360 | 570 | M24×50 | ||

| GZZ405 | 250 | 140 | 390 | 80 | 155 | 255 | 1070 | 405 | 400 | 340 | 194 | 390 | 60 | 390 | 580 | M24×50 | ||

| GZZ440 | 315 | 150 | 430 | 85 | 165 | 260 | 1140 | 440 | 440 | 375 | 208 | 410 | 65 | 420 | 650 | M24×50 | ||

| GZZ475 | 400 | 155 | 460 | 85 | 165 | 265 | 1180 | 475 | 480 | 415 | 220 | 450 | 70 | 460 | 684 | M36×70 | ||

| GZZ510 | 500 | 160 | 490 | 90 | 180 | 310 | 1280 | 510 | 520 | 430 | 245 | 480 | 700 | 80 | 500 | 770 | M36×70 | |

| GZZ550 | 630 | 160 | 510 | 95 | 180 | 310 | 1300 | 550 | 550 | 470 | 252 | 510 | 85 | 520 | 800 | M36×70 | ||

| GZZ580 | 750 | 165 | 515 | 98 | 185 | 320 | 1315 | 580 | 560 | 485 | 258 | 525 | 90 | 540 | 850 | M42×80 | ||

| GZZ610 | 840 | 225 | 580 | 105 | 210 | 360 | 1550 | 610 | 610 | 520 | 280 | 580 | 100 | 600 | 940 | M42×80 | ||

| GZZ660 | 1050 | 245 | 640 | 115 | 230 | 390 | 1690 | 660 | 660 | 540 | 295 | 630 | 100 | 650 | 990 | M42×80 | ||

| GZZ710 | 1300 | 265 | 680 | 125 | 250 | 410 | 1800 | 710 | 710 | 580 | 315 | 680 | 110 | 700 | 1070 | M42×80 | ||

| GZZ760 | 1600 | 290 | 730 | 135 | 260 | 430 | 1920 | 760 | 760 | 620 | 340 | 740 | 120 | 750 | 1150 | M42×80 | ||

| ROLL END CONNECTION SIZE |

REDUCER END CONNECTION SIZE |

QUALITY kg |

ROTATIONAL INERTIA kg ㎡ |

|||||||||||||||

| d3max | H2max | L 3max | L 4max | C |

d4 (H8) |

d5 (H7) |

d6 (JS10) |

m×z | n×d7×H3 | L 5 | L 6 | L 7 | Lmin |

For every 100 mm growth |

Lmin |

For every 100 mm growth |

||

|

Nominal dimension |

Extreme deviation |

Nominal dimension |

Extreme deviation |

|||||||||||||||

| 125 |

+0.20 +0.10 |

95 |

+0.20 +0.10 |

135 | 175 | 10 | 155 | 130 | 110 | 4×36 | 6×M10×25 | 35 | 85 | 120 | 150 | 4.77 | 0.75 | 0.024 |

| 150 | 110 | 195 | 235 | 15 | 195 | 170 | 150 | 4×46 | 6×M10×25 | 35 | 90 | 125 | 207 | 6.80 | 1.62 | 0.05 | ||

| 165 | 120 | 205 | 245 | 220 | 195 | 175 | 4×46 | 10×M10×25 | 40 | 95 | 130 | 291 | 8.88 | 2.95 | 0.09 | |||

| 180 | 130 | 210 | 250 | 220 | 195 | 175 | 5×42 | 12×M12×30 | 45 | 100 | 132 | 322 | 9.48 | 3.62 | 0.11 | |||

| 195 |

+0.25 +0.15 |

150 |

+0.25 +0.15 |

210 | 255 | 245 | 220 | 200 | 5×46 | 12×M12×30 | 50 | 100 | 150 | 460 | 13.87 | 6.45 | 0.19 | |

| 195 | 150 | 215 | 255 | 260 | 240 | 220 | 5×50 | 12×M12×30 | 50 | 100 | 150 | 507 | 18.67 | 7.99 | 0.29 | |||

| 220 |

+0.35 +0.20 |

170 |

+0.35 +0.20 |

230 | 275 | 25 | 280 | 260 | 240 | 5×54 | 12×M12×30 | 50 | 100 | 150 | 650 | 19.98 | 12.36 | 0.38 |

| 240 | 180 | 240 | 285 | 305 | 280 | 260 | 5×58 | 12×M12×30 | 50 | 110 | 155 | 785 | 23.2 | 16.09 | 0.48 | |||

| 260 | 190 | 250 | 295 | 336 | 306 | 276 | 6×54 | 12×M16×40 | 50 | 115 | 155 | 836 | 26.67 | 20.23 | 0.65 | |||

| 280 | 210 | 272 | 317 | 365 | 330 | 300 | 6×58 | 12×M16×40 | 50 | 115 | 155 | 1032 | 29.84 | 29.11 | 0.84 | |||

| 300 |

+0.40 +0.25 |

230 |

+0.40 +0.25 |

300 | 355 | 30 | 390 | 345 | 315 | 6×62 | 12×M16×40 | 50 | 130 | 170 | 1531 | 37.01 | 49.78 | 1.20 |

| 320 | 240 | 320 | 375 | 400 | 370 | 320 | 6×64 | 12×M16×40 | 50 | 130 | 170 | 1537 | 39.15 | 58.12 | 1.48 | |||

| 340 | 260 | 325 | 388 | 405 | 370 | 320 | 6×66 | 12×M16×40 | 50 | 135 | 175 | 1769 | 41.04 | 74.39 | 1.73 | |||

| 400 | 300 | 420 | 470 | 35 | 455 | 420 | 370 | 8×54 | 12×M20×50 | 50 | 160 | 210 | 2492 | 48.34 | 115.9 | 2.25 | ||

| 420 | 320 | 440 | 500 | 485 | 440 | 400 | 8×58 | 12×M20×50 | 60 | 180 | 230 | 3178 | 53.65 | 173 | 2.92 | |||

| 460 | 350 | 480 | 540 | 40 | 530 | 475 | 430 | 10×50 | 12×M20×50 | 60 | 190 | 240 | 3693 | 61.18 | 232.7 | 3.85 | ||

| 500 | 380 | 530 | 590 | 570 | 515 | 470 | 10×54 | 12×M20×50 | 60 | 200 | 250 | 4592 | 71.27 | 331.5 | 5.15 | |||

Note: The quality and rotary inertia are approximate values that calculated according to the max diameter of cylindrical shaft hole, when the total length reaches the minimum valve.