Structure and Application of Grid Couplings

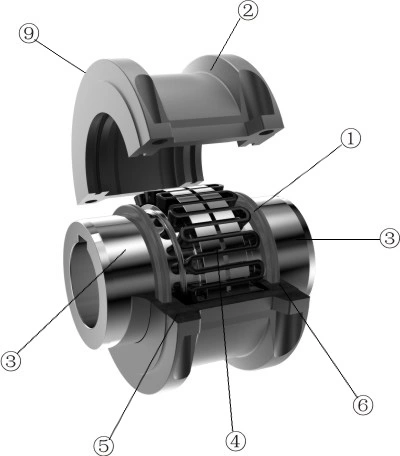

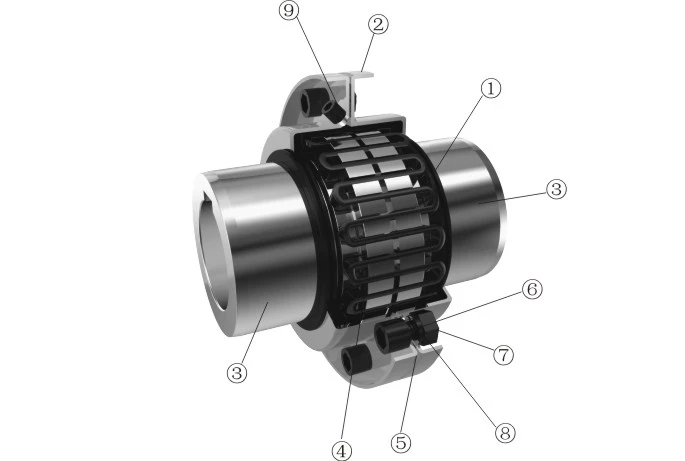

A grid coupling, just as shown in figure 1, figure 2, is made up of several groups of serpentine springs which surrounding tooth space of two half a couple to transfer movement and power. The external enclosed cover prevents the spring from being thrown under the action of centrifugal force. Lubricating oil exists inside cover, which lubricating the contact between spring and the tooth surface in case of dry friction.

1.Seal ring

2.Outer cover

3.Hub

4.Spring

5.Sealing gasket

6.Bolt

7.Nut

8.Spacer

9.Oil plug

8.Spacer

9.Oil plug

The grid couplings having compact structure, small overall dimension and operational reliability, are suitable for connecting transmission shaft of the two coaxial lines having medium or high power. The grid couplings have the functions that compensates certainly relative offset of two coaxial line, shock absorption and cushioning performances. Working temperature ranges from -30 ℃ to + 150 ℃ and the nominal torque is 52 ~ 931000 Nm. Generally two axis’ relative allowable displacement: the axial is 4 ~ 20 mm; the radial is 0.5 ~ 3 mm; the angular displacement is 1 ° 15 '. The gird coupling is widely used in various industrial fields.

The tooth surface of zigzag spring on grid couplings provided by Suoda adopts the arc design. When the torque growing, the distance of contact point between springs and the tooth surface decreases with the increasing of torque. The stiffness of springs increases, which is especially suitable for the occasions where torque changes variously.

The arc surface of spring in grid couplings of Suoda is manufactured by using patented technology, dedicated devices and special cutters, to ensure the technological advancement and accuracy of manufacturing.

The aluminum alloy cover of zigzag spring provided Suoda are designed to have the positioning structure, which prevents zigzag spring axial movement; What’s more, the mounting hole on aluminum alloy cover can prevent cover from being installed mistakenly in terms of design.

The zigzag spring of Suoda grid couplings adopts trapezoidal cross-section design. Spring can keep better contact with tooth surface. The grid couplings have stronger vibration absorption ability and can buffer the impact load to protect the driving and driven equipment.

Grid coupling has the cover that can be used in vertical and horizontal installation.

The cover of grid coupling can be disassembled easily which is convenient for replace zigzag springs and saves cost.

The design features of cover installed horizontally (figure 1): small space; aluminum alloy cover; light weight; small rotational inertia; suitable for reversing applications; easy to replace the zigzag springs.

The design features of cover installed vertically (figure2): suitable for high speed applications; covered made from high strength drawing steel; light weight; small rotational inertia; easy to replace the zigzag springs.

The design features of assembled style cover horizontally installed: suitable for pump applications; aluminum cover; light weight; small rotational inertia; easy to replace zigzag springs.

Structural Types of Grid Couplings

Model Selection of Grid Couplings

Rapid Cooling Setup and Connection of Grid Couplings

Carrying and Storage of Grid Couplings

Installation and Adjustment of Grid Couplings

Usage and Maintenance of Grid Couplings

Basic Info for Model Selection of Grid Couplings